Basic HTML Version

Free Technical Assistance... 800-873-2000

© 2011

16

Gabriel First Corp. • East Rochester, NY 14445-0191

Products that make up the

Novolac

Epoxy System

Prepare floors & walls using our regular cleaning and prep products.

1. Products used after preparation but before top coating.

a.

No. 8142-8203 ...

Novolac

Joint Sealant

(1.25 or 2.5 GL Kits)

b.

No. 8142-8206 ...

Novolac

Crack Filler

(1.5 or 3 GL Kits)

c.

No. 8142-8209 ...

Novolac

Mortar Grout

(1.5 or 3 GL Kits)

2. Apply the following

Novolac

top coating products.

a.

Novolac

Primer

*CLEAR

No. 8142-8212 ...

Chemical-Resistant

(3 or 15 GL Kits)

b.

Novolac

Sealer/Finish

*CLEAR

No.8142-8215....

Chemical-Resistant

*Colors Available on Special Order

Novolac

epoxies resist chemicals

better than do regular epoxies. The

increase is about 30%. For example,

chemical resistance to sulfuric acid

increases from an immersion service

concentration of 70% to 98%.

Outstanding Chemical & Heat Resistance

Bottom Line:

Novolac

epoxy coatings

are designed for application where

splashes and spills of acids, chemicals,

and solvents occur.

Novolac Epoxy

exhibits excellent resistance to strong acids,

alkalis, and most industrial chemicals and solvents.

• May be applied in cool damp conditions.

• May be re-coated in 4 to 6 hours.

• May be applied in occupied facilities.

• Forms a virtual moisture barrier.

Typical

Chemical Process Plants • Petroleum Facilities • Pulp & Paper Mills

Uses

Food Processing Facilities • Gas Processing • Mining Industry

Battery Charging Stations • Sewage & Water Treatment Plants

Always consult with a Gabriel Concrete Specialist before proceeding

with using

Novolac Epoxy

products. We have a comprehensive set of

Novolac Epoxy

products as well as the technical expertise to guide you.

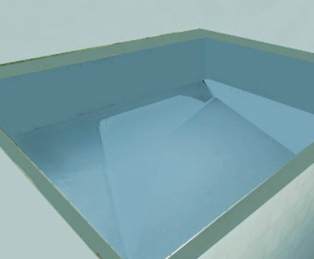

Secondary Containment

Chemical Storage Room

Novolac

Chemical-Resistant Epoxy System