Basic HTML Version

Free Technical Assistance... 800-873-2000

© 2011

2

Gabriel First Corp. • East Rochester, NY 14445-0191

Clean—Remove Soil

To best define

Clean

, the surface to

which a product is to be applied must be in a

condition that will allow a fully-connected

bond between the primer and concrete.

A100% bond must be from the final top coat

all the way down into the concrete voids.

That said, there are conditions that can

weaken a bond—general soil, excess oil,

grease, and/or fat impregnation, excess

concrete dust, paint or high-build epoxy,

silicone residue, etc.

Moisture Testing &

Corrective Actions

(

Optional

)

As moisture vapors move up in the concrete,

soluble alkaline materials such as sodium,

potassiumand calciumhydroxides alsomove.

As corrosive materials become concentrated

in the upper portions of the concrete,

they can damage the flooring systems or

the concrete itself. The damage may be

evidenced by coating separation, surface

crumbling, moisture vapor bubbles, adhesive

breakdown (e.g. black oozing around floor

covering seams), and mold or staining.

The goal of moisture vapor remediation

is to keep excessive moisture and soluble

corrosive alkalinity isolated from the

flooring system by creating a strong

moisture barrier on the concrete surface.

A barrier sealer must not allow moisture

vapor to push primers and coatings away

from the concrete surface.

To determine the extent of any moisture

vapor pressure, you will need to perform the

Anhydrous CalciumChlorideMoisture Test

.

The test kits are available from flooring

supply wholesalers and Internet vendors.

If testing shows moisture pressure greater

than 3 lbs., check with a Gabriel Concrete

Specialist for remediation options.

If the floor has had problems that cause

suspicion or you will be doing a sizable

area, it is well worth the time and effort

to perform the testing.

Concrete... Preparation Is Key to Success

The best concrete coating may temporarily hide a substrate’s

physical defects, but it cannot correct them... And, they will return!

Damaged substrates must be prepared correctly to ensure success.

Always begin with a perfectly clean and profiled (e.g. etched) surface.

Following the preparation, a primer must be applied to the bare concrete.

The following steps are listed in the order of normal performance.

Not all of the steps listed below are required for every job.

2

1

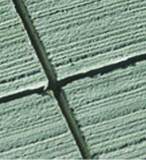

Filling Expansion or Control Joints

Expansion Joint

board is erected before the

pouring to form smaller slabs, provide space

for slab expansion, and help prevent cracking.

Control Joints

get cut into set concrete

to help route future cracking to the cut.

Control Joint

cutting depth should be 25%of

the depth of the slab. Cuts need to be made

a few hours after concrete placement.

Patch Cracks and/or Replace Missing

Concrete to Restore Floor Integrity

Gabriel

Con-Patch

Epoxy Mortar enables

no-breakaway patching by permanently

locking to the old concrete. Cracks less

than ½” wide and/or 2” deep need to be

opened more by using a crack chaser,

hammer drill, etc. Clean-out and vacuum

the cavity well. If on-grade floor slabs

have dropped or moved, call Gabriel for

advice on how to correct the problem.

Joint Board

Extends the

Full Depth of

the Concrete

Control

Joints

Fill cuts with Flexible Joint Compound.

Expansion Joint

1. Crack chaser opens a perfect seam.

2. Seams are filled with

Con-Patch

.

Board may be pulled and the space

filled with Flexible Joint Compound.

Cutting

Finished